In the last few years there has been an increase in the use of epoxy resins in timber-framed repairs, despite some reservations by such bodies as the Society for the Protection of Ancient Buildings. Its use should be restricted to situations where traditional repairs in timber are not desirable or practicable – for instance, where it would cause undue disruption to the fabric of the building or where access is difficult or for reasons of economy. Although there is concern that the resin can deface the timber and cause condensation, with subsequent rot and insect-attack to the adjacent timber, the joint is very strong, and though one might expect any thermal or stress movement to occur

here, in practice any such movement occurs with the structural joints.

Its principal use is in end-beam repairs where ends of beams or roof trusses have been subject to decay. The decayed section of timber is cut away, and glass fibre reinforcing rods are inserted into holes, drilled at an angle into the sound timber and set in position with epoxy resin paste or grouted in with low-viscosity epoxy resin and epoxy resin filler mortar. The mortar is usually composed of epoxy resin mixed with an inert material such as very fine silver sand. The cavity should be thoroughly cleaned to remove all frass and debris and brushed with a low-viscosity epoxy resin, feeding as much as possible into the areas softened by rot or excavated by beetle-infestation. Shuttering is formed to the shape of the removed section and the epoxy resin mortar poured into the shuttering and around the reinforcing rods. The mortar should be well rammed into the decayed profiles to ensure the exclusion of air pockets. When the shuttering is removed, the beam is finally shaped. Alternatively, where the repair is visible, permanent oak shutters are pieced into the surviving sound faces and glued and dowelled to finish proud of the required finished face for subsequent working back on completion of the repair. Prior to the application of the resin, the shutters and adjacent surviving timber should be protected from resin spillage and runs, with two coats of peelable rubber latex. The repair is carried out as described above but the mortar level is left below the top of the side ‘shutters’ to allow for cutting, fitting and pinning a timber slip on top of the repair before the mortar is cured. After curing, the latex coating is stripped off and the timber shutters are shaped and cut back as appropriate to the correct face.

Along the same lines timber joints can also be restored when they are decayed, without the aid of steel straps and bolts. However, care should be taken for it is important that joists retain their original freedom of movement, and although it is claimed that such repaired joints allow some degree of movement, in most cases the joints should be dismantled and repaired to allow for all the original movement to take place. This is achieved by building up the decayed section with resin which can then be worked freely to the original joint profile. In addition these resins can be used as hardening agents injected into partially decayed timbers, providing them with additional strength while retaining the original detail. Shakes, splits and holes can also be treated by brushing and blowing out with compressed air all loose frass and debris and treating the area with low-viscosity epoxy resin well brushed in, allowing all softened areas to absorb as much resin as possible before the void is packed with epoxy mortar finished off level and dusted with wood ‘flour’.

Epoxy resin is now used in timber repairs in many European

countries, as well as Canada and USA, and long and intensive field trials have proved to be very successful. In recent years it has been used on a number of important timber-framed buildings in Britain, including those under the Directorate of Ancient Monuments and Historic Buildings. The work is generally undertaken by a specialist firm.

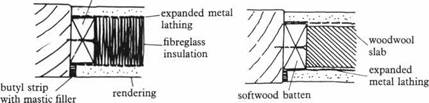

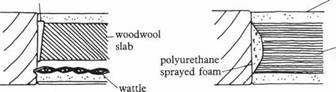

As we have seen previously, wattle-and-daub was the traditional infilling to the walls of a timber-framed structure but, although internally much remains in good repair, externally much is defective, for the wattle is usually infested with beetle or, because of water penetration through the daub, is rotten and needs replacement. When only an odd panel needs replacing, the wattle can be renewed using the traditional methods as previously described, with the wattle being covered by one of the methods described later. As is more often the case, however, it will be found that most of the panels are defective and in need of replacement, and a number of renewal techniques are available, the choice depending largely on the size and shape of the panels (209).

Lightweight blocks cut and fitted between the studs and jointed in mortar, in the same way as brick-nogging, rendered externally and plastered internally, are sometimes used, but they are not to be recommended for they can create problems in overloading the frame, as well as the difficulty in making a satisfactory watertight joint between the blocks and timber.

|

softwood batten screwed to stud

plaster |

|

|

|

wedge |

|

polyurethane sheet |

|

daub with skim coat |